News Date:2017-07-05

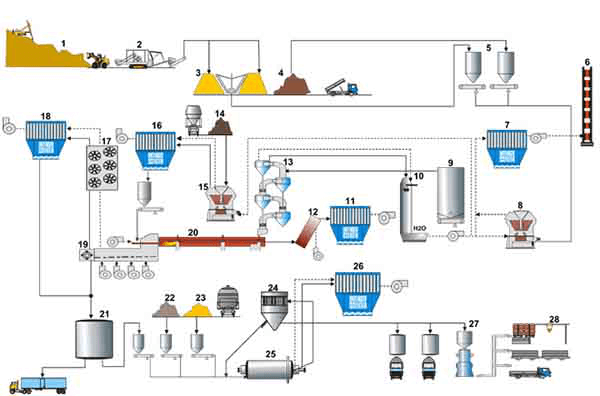

crushing and storage——Dosing——Limestone‘s crushing and storage——Dusting collecting system——Raw meal homogenizing——Raw mill grinding (Raw mill)——(Coal homogenizing——Coal mill grinding)——Preheating and precalcining system——Rotary kiln calcined (rotary kiln)——Cooler——Clinker storage——Cement Grinding (cement mil)——Additive material crushing——Cement storage——Transportation in bag——Transportation in bulk

Raw material vertical mill: limestone, clay raw materials and a small amount of correction materials by crushing after a certain proportion with the grinding.

Rotary kiln calcination: the raw material in the cement industry kiln calcined to some of the melting, after cooling to calcium silicate as the main component of the clinker process.

Cement clinker vertical mill: the clinker added gypsum, other mixed materials together with the vertical mill equipment into a cement product.

Coal vertical mill: to provide the required heat for the calcination of the rotary kiln, providing a strong guarantee for the production of cement clinker.

| How to good use the steel slag vertical mill products(steel slag powder)? | The fuel material blast furnace gas and bio-fuels for slag production line | Return column |