News Date:2019-11-01

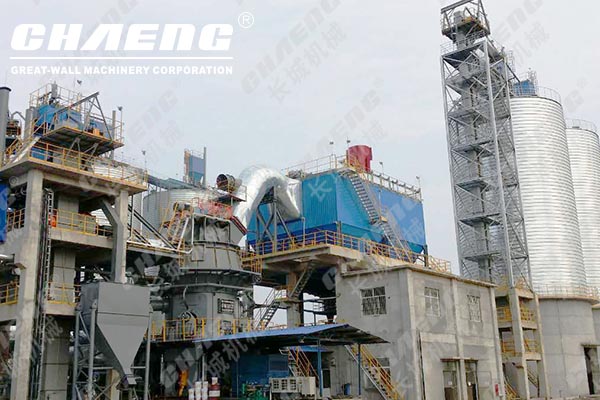

Vertical mill can be integrated into fine crushing, grinding, drying, powder selection and conveying. It can grind various industrial waste residues, help the steel plant to realize the effective utilization of slag resources and improve the overall environmental and economic benefits. When dealing with steel slag, due to various factors such as poor grindability and poor stability of the steel slag, it is necessary to improve the vertical mill to adapt to various problems when grinding steel slag.

Increase multiple iron selection

In the steel slag into the grinding and other places to increase the selection of iron, screening the excess metal iron in the steel slag, before the grinding, after the purification of iron removal, the steel slag tail metal metal content is less than 2%, the fineness is less than 10mm, After grinding by GRMSS steel slag vertical mill, the specific surface area of ??steel slag powder is 400-500m2/kg, which fully achieves the expected effect, is environmentally friendly and efficient, and realizes high-value resource utilization of steel slag.

Increase multiple wear resistance

In the running process of the vertical roller mill, the grinding roller and the grinding table are mutually pressed. In order to ensure the life of the vertical mill, it is necessary to add a wear layer on the grinding roller and the grinding disc. Because of the poor grindability of the steel slag, it is necessary to thicken the wear layer on the vertical mill grinding roller and the grinding disc to perform multiple wear resistance. The multi-layer surfacing of the wear-resistant layer of chaeng shows our advanced technology to ensure the service life of the vertical mill.

| Viewing the advantages of vertical mill from the development of steel slag grinding equipment | What technical improvements have been made to GRMSS series of steel slag mills? | Return column |