News Date:2015-09-14

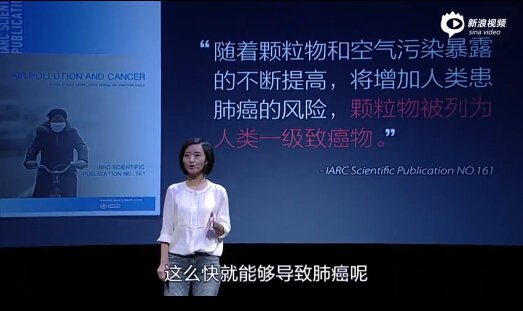

As the surging of the particulate matter and air pollution exposion, particulate matter is ranked the first grade cancerogen of the lung cancer for human being.On March 1, Chai Jing broadcasted her large investigation documentary under the dome in CCTV , it caused a quite stir.

The documentary "Under the dome " was 103 minutes long, by interviewing more pollution sites to seek root cause of the smog, Chai Jing filmed the pollution treatment experience in many countries field ,and analyzed what is root reason of the pollution.

This pollution documentary was released before The NPC and CPPCC sessions, its intention may need to put pressure on The NPC and CPPCC sessions. How further to change economic growth way , how to ascertain all parties protection responsibility of ecological environment , and how to a series of pollution problem such as "smog everywhere " etc. all above questions will become the reference points to Chinese government economy development.

In this special investigation subject, Chai Jing mentioned the most of PM2.5 mainly came from burning coal and fuel oil, Therefore, in order to solve the smog and reduce emission, one of the effective way is to deduct the consumption of burning coal.

Each individual has its own way to deduct the dosage of burning coal, as the steel and iron enterprises being mentioned in this documentary, they are well worth doing more to decrease the emission and dosage of the burning coal.

We understand now, slag processing is a troublesome difficult problem during the business running process of the steel-iron enterprises. According to statistical result of the relative associations, at present all of our country’s factories are producing over 90 million tons of slag every year, and the slag quantity is still increasing now, however, the slag comprehensive utilization rate of Chinese steel works is just 10%, there is still a large distance compared to the 75% target of “a batch of industrial waste residues comprehensive utilization during the 12th five years” of the Ministry of the Industry and Information Technology.

In recent years, Slag powder, as the cement concrete admixture, has already become the important way of the steel slag process, through a reasonable blending ratio, it may improve the cement intensity and the concrete properties.

Being worth paying attention to, it will reduce magnanimous consumption of burning coal and carbon dioxide to use the slag powder to replace cement linker to produce the cement and concrete.

1, Each production of one ton cement directly consumes 114 kg fire coal, If every year there are 50 million tons of waste slag which can be used for the production of steel slag cement, it can save 5.7 million tons standard coal every year.

2, The production of one ton slag powder consumes less 60 kw/h electric power than the production of one ton cement, if production quantity is up to 50 million tons of slag each year, it may save 3 billion kw/h electric power which is equal to the consumption of 1,240,000 tons of standard coal.

3, In the field of carbon dioxide emission, it will emit 1.095 tons of carbon dioxide to produce each one ton cement , If every year the whole 50 million tons waste slag can be used for the production of mine slag cement and steel slag cement, the carbon dioxide emission will decrease total 54,750,000 tons every year.

In the investigation documentary, Chai Jing asked the expert of Chinese Academy of Science how to keep the APEC blue sky, that expert's simple reply is that we need to reduce half quantity of the pollutant to have the possibility to get the blue sky.

Steel slag’s comprehensive utilization can be used as the cement concrete admixture to replace cement linker, the saved emission will be a big giant quantity.

As the domestic first-rate industry waste slag powder integration supplier and service merchant, The Great Wall machinery co., LTD has developed the most advanced new type steel slag processing technology and GGBS Vertical Roller Millthrough the continuous exploration, practice and research in the past several years.

The effect of energy saving is quite obvious, and waste slag utilization ratio is very high, it has made enormous contribution for steel slag’s comprehensive utilization development and the solution of environmental protection in China.

It needs each of our people and each of our enterprises to take its own responsibility to reduce the emission and control the smog, Chairman Xi Jin Ping said: "I hope to believe that APEC blue sky is able to be kept through our indefatigable effort ".

Here, The Great Wall machinery co., LTD strongly call for that each industry shall accelerate transforming of the development way, decrease the usage and emission of higher pollution energy sources, contribute our effort for the green power and energy-saving Chinese economy development.

| Four factors should pay attention when buy the vertical mill | The Great Wall Machinery innovates the sales pattern, fights for the transformation and upgrading | Return column |