Introduction

Rocker is one of key components of vertical grinding mill. It includes upper rocker, down rocker, rocker shaft, bearing, bearing seat, etc. The upper rocker is used to install the grinding roller, and the down rocker connects with hydraulic system. Two rockers are connected into a whole by shaft, taper sleeve and taper pin.

Advantages

1.The rocker produced by Great Wall Casting has better wear-resistant capability and good anti-cracking.

2.We carry out the dressing and finishing by arc air gouging and shot-blasting for the steel castings to guarantee the appearance quality.

3.Before delivery, all the rockers will have NDT inspection several times as per perfect inspection flow. Any defective product is forbidden to leave factory.

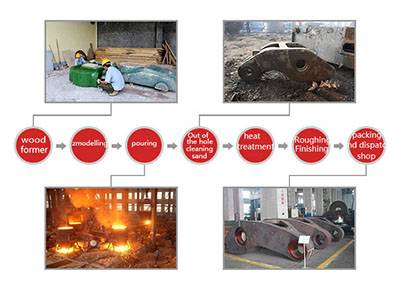

Process

Case

There are many customers in China. The steel casting products can meet both requirements of domestic production process, and international advanced production standards. It have won a good reputation from new and regular customers especially in Tianjin, Henan, Hebei, Dalian, Tangshan etc. because of its good post operation. The casting products ensure the vertical mill’s effective operation.

From day one, GREAT WALL Machinery has been seeking win-win solutions together with our customers by creating an extensive service network.

At the core of our service system is a professional team that delivers standard, high-efficiency, and consistently good-quality services. Presently, our service network covers Central China, East China, Southern China, Northern China, and Northwestern China, among various other regions. As our sale is still on the increase, we take steps to improve our after-sales service system. At the moment, we are expanding our service area beyond China to countries all over the world.