Introdution

Lime rotary kiln is the main equipment of lime production line. It is widely used for many industries like metallurgy, chemical industry, building refractory materials, environmental protection, etc.

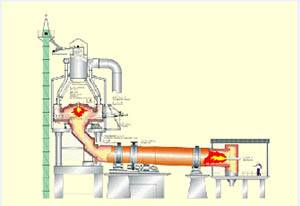

The rotary lime kiln consists of cylindrical shell, supporting device, supporting device of thrust roller, driving unit, moveable kiln head, sealing device on the tail of kiln, coal dust pipe device, etc., the kiln body has a certain tilt angle with level.

The whole kiln body is supported by the roller supporting device, and it is also equipped with thrust roller device to control the up and down movement of the kiln body.(send us a inqury for more data about it)

Features

High Automation Level

The lime rotary kiln is with advanced structure. Its pre-heater with low-pressure loss can improve preheating effect efficiently. After preheating, the resolution ratio of the lime-stones can reach 20~25% when they enter the kiln. Besides, the lime-stones, with fine fraction about 10~15mm, can be used directly.

Waste Heat be Reused Effectively

The two sides of the reliable rotary kiln are sealed by the combined scales, which can make the air leakage coefficient less than 10%. Composite refractory materials should be used in order to reduce the loss of radiant heat.

Low Energy Consumption

The filling vertical cooler, round or square, can be zoned-ventilation, which can make the temperature of lime-stones in the cooler at about 80°C. As a result, it is very convenient to transport and store. It can also pre-heater the secondary air up to the temperature above 700°C, then the waste heat can be recycled to reduce energy consumption.

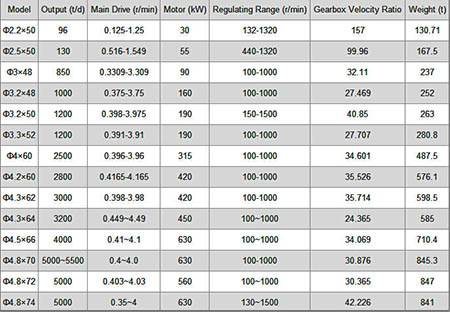

Specifications