Service and Solution

We can provide technological solutions and complete production equipment for quicklime (active lime) production line.

-Design capacity:50-700TPD

-We have professional engineer team.

-We have mature experience, and project cases more than 100 till 2011.

-We use the new tyoe, energy saving and environmental system, through which fuel consumption can be reduced 40%, output capacity increased 30%.

Production process description

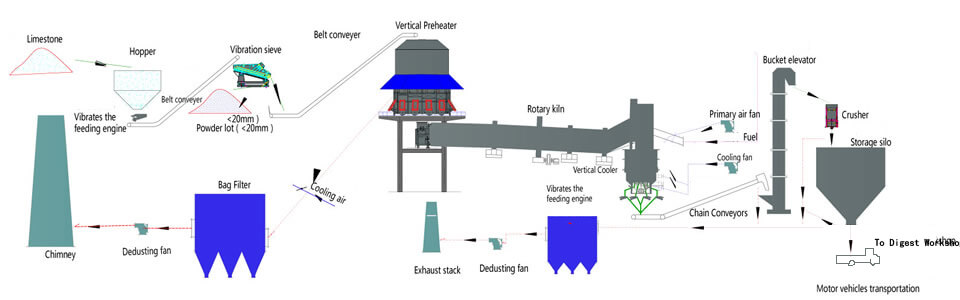

1.Raw material feeding

limestone in the plant yard will be carried by tractor shovel and fed to hopper, it will be discharged from hopper to vibrating feeder and sent to vibrating screen for screening through belt conveyor. The size ≥20mm will be sent to pre-heater by conveyor. And size less < 20mm will be carried away.

2.Calcination

limestone in the pre-heater will be preheated by the hot air, then it will be discharged to rotary kiln through chute that connecting pre-heater and kiln, it will stay in the kiln for 1.5-2 hours for calcination, during the process, it will be calcinated with temperature around 1300 ℃, after which comes limestone decomposition and release of co2,then the for mation of quick lime qill be completed.

3.Lime conveying

Lime will be discharged to a chain conveyor by vibrating feeders in the bottom of vertical cooler, it will be lifted to lime in the storage hopper can be used for dispatch or transported to the hydration workshop.

4.Dust filtering .

There are two dust filtering systems, one is in the kiln inlet, dust will be filtered by bag filter then the clean gas will be released to air. The other is dust from lime storage hopper and the feeding part of bucket elevator, dust will be filtered by bags and then released to air.

Advantages of Our lime plant

The calcination process adopts pre-heater+ rotary kiln+ vertical cooler system, , it can reduce the fuel consumption 40%, increase output capacity 30% due to reuse the waste gas in the system. The other advantages are in the following.

1.The lime quality is very good and high activity.

2.It is especially suitable for large-scale lime production.

3.The production running is stable, the whole process using negative pressure, air flow freely and high production safety

4.Using the bag filter system, it can reduce the exhaust gas less than 50mg/Nm3

5.It shorten kiln length, reduce heat loss and area.

6.Cooler and kiln hood cover designed together, good seal, saving area.