News Date:2017-03-18

In recent years, rotary kiln market has developed rapidly and highly competitive. Many rotary kiln equipment manufacturers in order to meet the new development requirements, to make a series of equipment production planning. Rotary kiln production equipment should focus on solving the problems facing the development of the industry. Continue to carry out product development and innovation, promote the use of new active lime rotary kiln equipment, Chaeng(Xinxiang Great Wall Machinery) is the development goals.

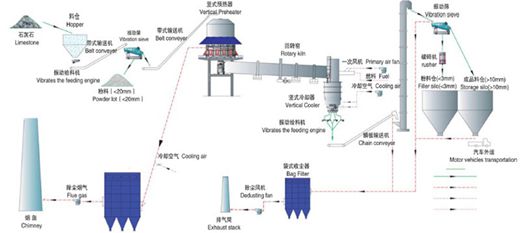

Chaeng Lime Rotary Kiln Craft:

Material from the kiln (the high end of the cylinder) into the kiln to be calcined. Due to the inclination of the cylinder and the slow rotation, the material is rolled in the circumferential direction and moved in the axial direction (from the high end to the low end), and the process of decomposition and firing is continued. After physical and chemical changes, Material through the kiln hood into the grate cooler cooling. Fuel from the kiln into the kiln, the combustion of waste gas and material after the heat exchange, derived from the kiln.

China's rotary kiln perfect technology beyond the self, Chaeng using advanced rotary kiln production technology, give full play to creativity, research and development of rotary kiln equipment, high technology content, with different advantages.

Chaeng Lime Rotary Kiln Advantages:

1, advanced technology, high production efficiency, good quality lime

Chaeng lime rotary kiln produced by the use of advanced structure, low pressure loss of the vertical preheater, can effectively improve the preheating effect, improve production efficiency, the lime quality is very good, lime activity ≥ 300 (ml), is Ideal energy saving and environmental protection lime kiln equipment.

2, energy-saving calcination, advanced calcination mechanism

Furnace design using fully sealed calcination mechanism, the kiln refractory insulation layer with multi-layer refractory material, mildly good, furnace refractory insulation layer design life in more than 5 years. In order to effectively use energy, the upper and lower parts of the furnace using heat exchange, greatly reducing the heat from the upper and lower parts of the loss.

3, the use of frequency converter, energy-saving equipment operation

The power used in the production of lime kilns are used in the inverter control and operation, to avoid the large horse and no-load no-load operation of the phenomenon, saving energy on average more than 40%.

| Steel Casting Slag Pot for Steel Mill | cement vertical roller mill casting steel spare parts | Return column |